Gray iron castings means the casting parts made of gray iron. Gray cast iron is a kind of iron-carbon alloy, and its section is gray, so it is called gray cast iron. In gray cast iron, carbon mainly exists in the form of flake graphite. As one of the widely used casting metals, cast gray iron has many advangates in costs, castability and machinablity. Tensile strength is the main performance index for measuring gray cast iron. Almost all countries use the tensile strength to classify gray cast iron.

The casting processes which are used for casting gray iron covers many methods. At our foundry, we usually adopt the sand casting, shell mold casting, lost foam casting, vacuum casting and even lost wax investment casting. However, the most widely used casting processes are sand casting, shell mold casting and lost foam casting. The gray iron castings have many advantages comparing to the castings of other metals and alloys..

Gray iron is cheaper than ductile iron, but it has much lower tensile strength and ductility than ductile iron. Gray iron can not replace the carbon steel, while the ductile iron could replace the carbon steel in some situation due the high tensile strength, yield strength and elongation of ductile iron.

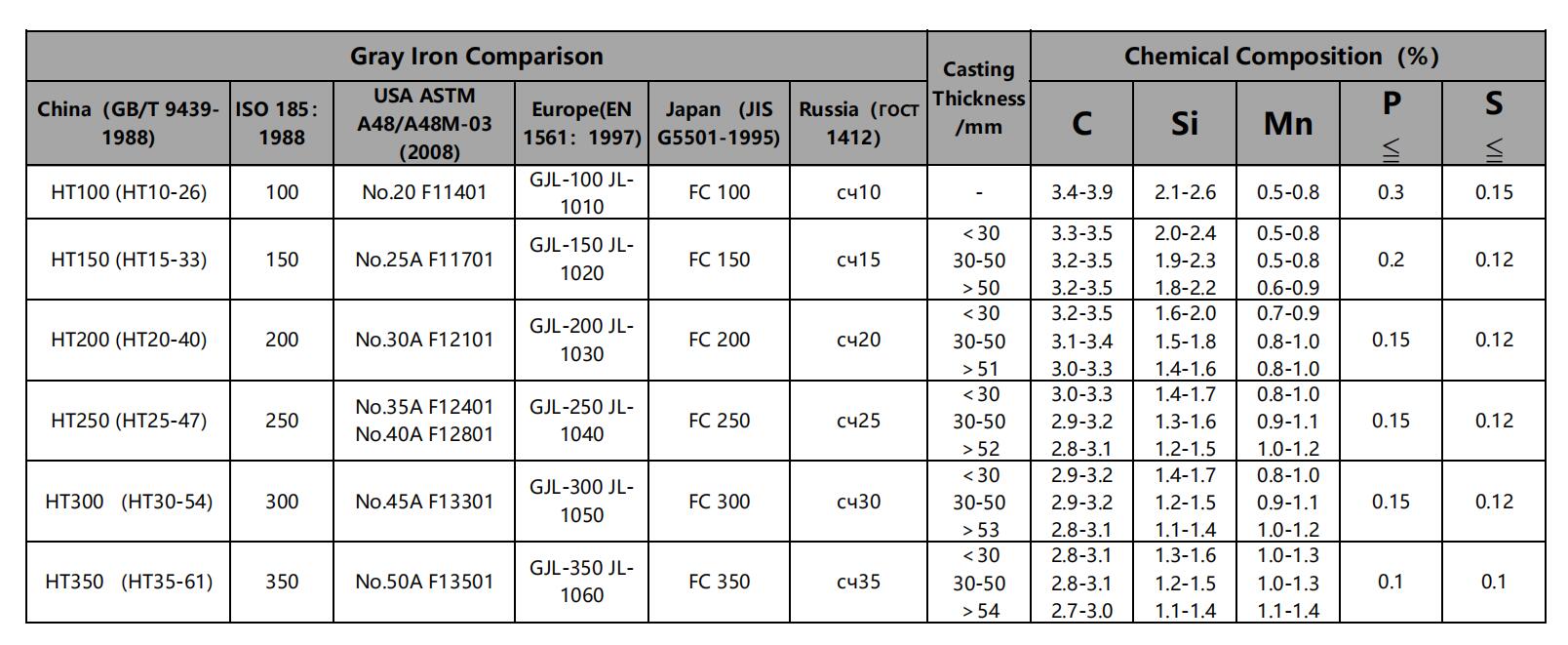

Gray Iron Chemical Composition

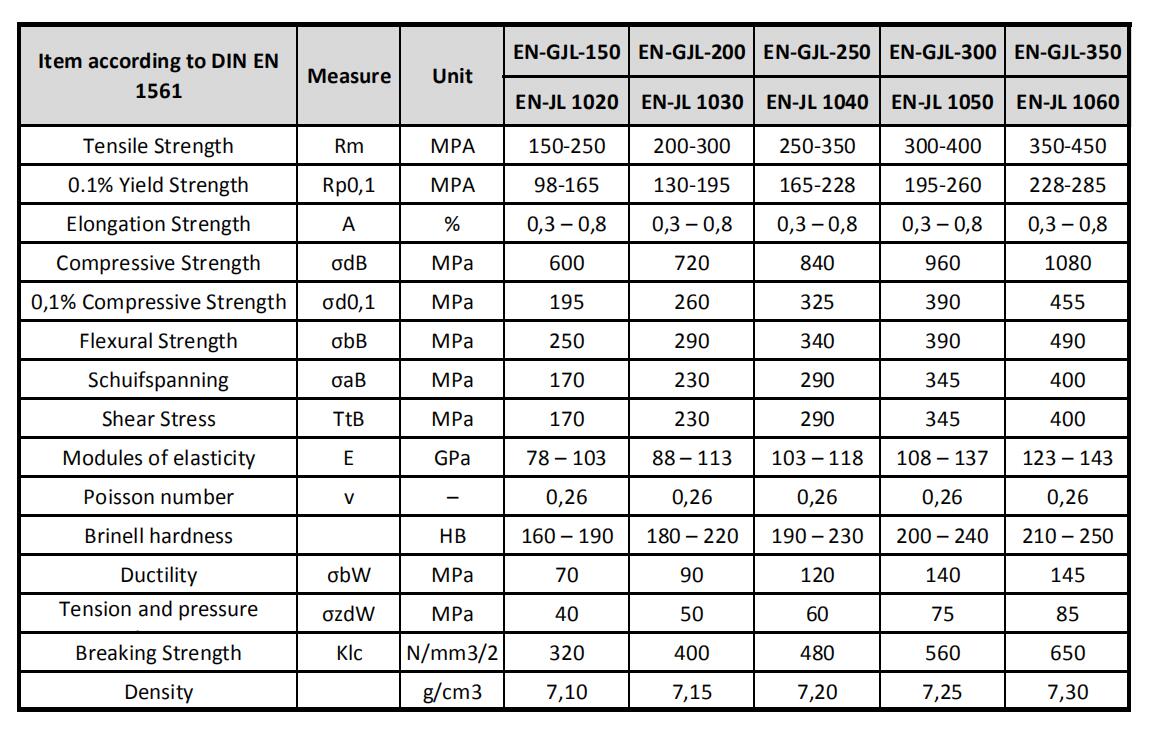

Mechanical Properties of Gray Cast Iron

русский

русский