Gray Cast Iron Investment Casting Product

Material: Gray Cast Iron, GG15, GG20, GG25, GG30 Casting Process: Investment Casting Weight: 2.50 kg Application: Bearing Housing

OEM gray cast iron investment casting product from China foundry. We also provide CNC machining, heat treatment, surface treatment and other custom services.

Custom Investment Casting Part of Grey Cast Iron from China Precision Casting Manufacturer

With reasonable price and rich engineering services, RMC Foundry could produce and provide OEM custom gray cast iron investment casting products from China foundry with silica sol investment casting process. Diverse materials to be available including gray iron, ductile iron, carbon steel, alloy steel, stainless steel and cast aluminium. Like ductile cast iron, the grey cast iron is usually cast by green sand casting or shell mold casting for normal castings, but if the customers need metal castings which need both high accuracy and good damping performance (shock absorbtion) such as the case, seats or bearing housing, then the investment casting process would be the best choice.

Mechanical Properties of Gray Cast Iron

Item according to DIN EN 1561

Measure

Unit

EN-GJL-150

EN-GJL-200

EN-GJL-250

EN-GJL-300

EN-GJL-350

EN-JL 1020

EN-JL 1030

EN-JL 1040

EN-JL 1050

EN-JL 1060

Tensile Strength

Rm

MPA

150-250

200-300

250-350

300-400

350-450

0.1% Yield Strength

Rp0,1

MPA

98-165

130-195

165-228

195-260

228-285

Elongation Strength

A

%

0,3 – 0,8

0,3 – 0,8

0,3 – 0,8

0,3 – 0,8

0,3 – 0,8

Compressive Strength

σdB

MPa

600

720

840

960

1080

0,1% Compressive Strength

σd0,1

MPa

195

260

325

390

455

Flexural Strength

σbB

MPa

250

290

340

390

490

Schuifspanning

σaB

MPa

170

230

290

345

400

Shear Stress

TtB

MPa

170

230

290

345

400

Modules of elasticity

E

GPa

78 – 103

88 – 113

103 – 118

108 – 137

123 – 143

Poisson number

v

–

0,26

0,26

0,26

0,26

0,26

Brinell hardness

HB

160 – 190

180 – 220

190 – 230

200 – 240

210 – 250

Ductility

σbW

MPa

70

90

120

140

145

Tension and pressure change

σzdW

MPa

40

50

60

75

85

Breaking Strength

Klc

N/mm3/2

320

400

480

560

650

Density

g/cm3

7,10

7,15

7,20

7,25

7,30

Grey cast iron (also called grey cast iron) is a group of cast iron including several kinds of grade according to different designation of diverse standards. Gray cast iron is a kind of iron-carbon alloy and it gets its name "grey" from the fact that their cutting sections looks grey. The metallographic structure of gray cast iron is mainly composed of flake graphite, metal matrix and grain boundary eutectic. During the grey iron, the Carbon is in the flake graphite. As one of the widely used casting metals, cast gray iron has many advangates in costs, castability and machinablity.

Performance Characteristics of Gray Iron Castings

- Liquid gray iron has good fluidity, and its volume shrinkage and linear shrinkage are small, and the notch sensitivity is small

- Low comprehensive mechanical properties, compressive strength is about 3~4 times higher than tensile strength

- Good shock absorption, the shock absorption of gray iron is about 10 times greater than that of cast steel

- Gray iron has low modulus of elasticity

Structural Characteristics of Gray Iron Castings

- Small wall thickness and complex shapes are available

- The residual stress of the casting is small

- Gray iron castings should not be designed with very thick structures, and asymmetrical sections are often used to make full use of their compressive strength

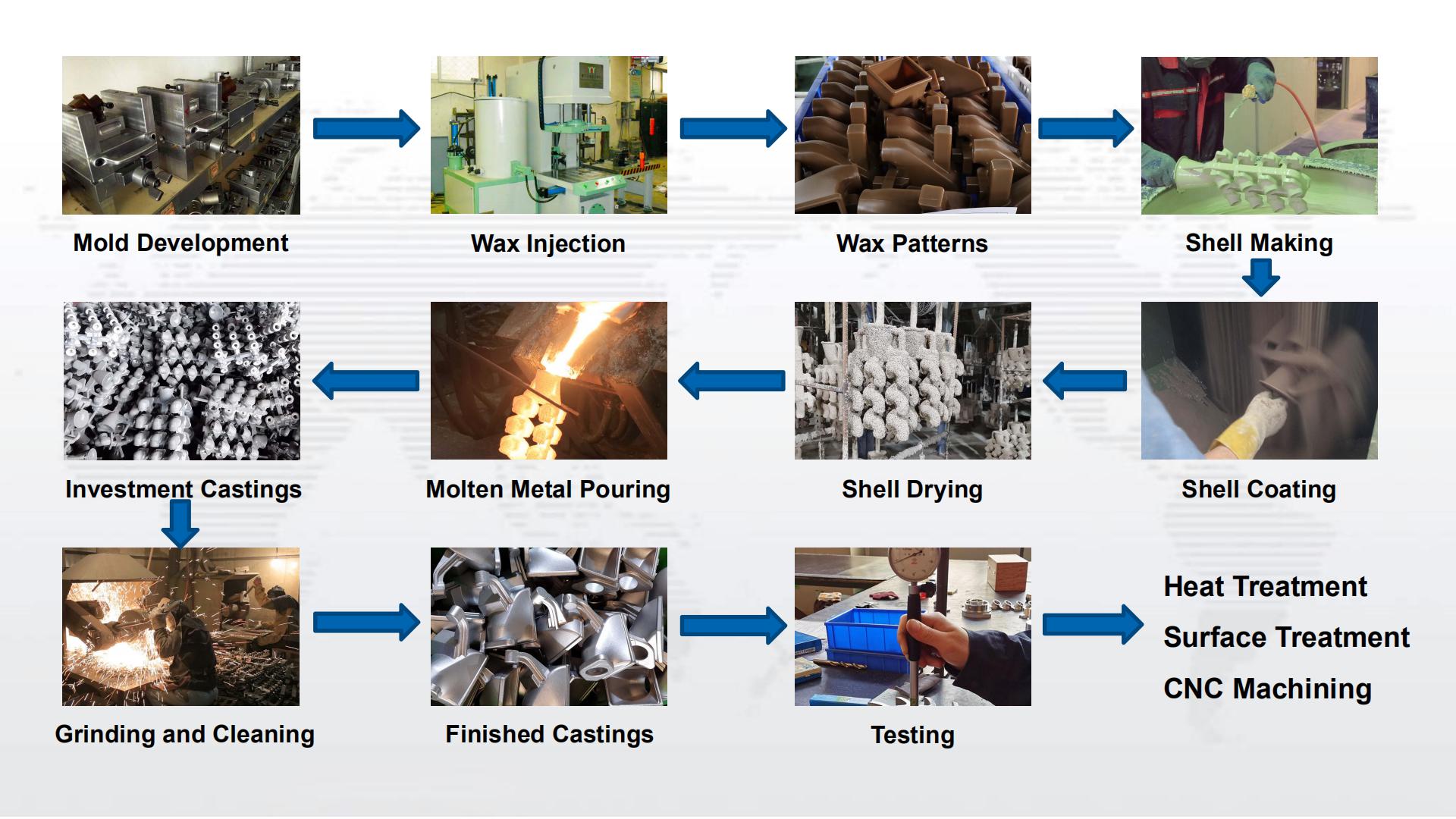

Investment casting, which is also known lost wax casting or precision casting, refers to the formation of ceramic around the wax patterns to create a multi or single part mold to receive molten metal. This process utilizes an expendable injection molded wax pattern process to achieve complex forms with exceptional surface qualities. To create a mold, a wax pattern, or cluster of patterns, is dipped into ceramic material several times to build a thick shell. De-wax process is then followed by the shell dry process. The wax-less ceramic shell is then produced. Molten metal is then poured into the ceramic shell cavities or cluster, and once solid and cooled, the ceramic shell is broken off to reveal the final cast metal object. Precision investment castings can achieve exceptional accuracy for both small and large casting parts in a wide range of materials.

What Are The Advantages of Investment Casting?

- Excellent and smooth surface finish

- Tight dimensional tolerances.

- Complex and intricate shapes with design flexibility

- Capability to cast thin walls therefore a lighter casting component

- Wide selection of cast metals and alloys (ferrous and non-ferrous)

- Draft is not required in the molds design.

- Reduce the need for secondary machining.

- Low material waste.

русский

русский