Gray Iron Sand Casting Manufacturer

Material: Gray Cast Iron Process: Sand Casting Weight: 8.12 kg Application: Oil Pan

Custom Gray Iron Sand Casting Manufacturer from China with CNC Machining Services. RMC is a sand casting foundry offering OEM custom iron sand castings.

Custom Gray Iron Sand Casting Manufacturer from China with CNC Machining Services. RMC is a sand casting foundry offering OEM custom iron sand castings.

Sand casting could be divided into several categories such as green sand casting, shell mold casting and dry sand casting. The green sand casting adopts the green (wet) sand to make the molding systems, while the shell mold casting adopts some resin coated sand. However, some sand casting foundries also take lost lost foam casting and vacuum casting as dry sand casting, just because the sand used for these two casting processes are dry and don't use any adhensive materials to make the molding systems.

If you are interested, you can visit our other pages to know more about other other castings processes and the comparion of them with green sand casting. The sand casting process offers the greatest flexibility and the most cost-effective tooling. Combined with the lastest equipment in sand casting technology and dedicated workforce, the sand casting foundry of RMC are able to tackle any desired requirements. Our sand casting components are serving many industries of high demand such as oil & gas, rail trains and automotive.

Cast iron is an iron-carbon cast alloy with other elements that is made by remelting pig iron, scrap, and other additions. For differentiation from steel and cast steel, cast iron is defined as a cast alloy with a carbon content (min 2.03%) that ensures the solidification of the final phase with a eutectic transformation.

Depending on chemical specifications, cast irons can be non-alloyed or alloyed. The range of alloyed irons is much wider, and they contain either higher amounts of common components, such as silicon and manganese, or special additions, such as nickel, chromium, aluminum, molybdenum, tungsten, copper, vana- dium, titanium, plus others.

Generally speaking, the cast iron could be divided into gray iron, ducitle iron (nodular iron), white cast iron, compacted graphite iron and malleable cast iron.

▶ Design and Development of Sand Casting Toolings and Patterns

We invite our customer to involve the design and development of the toolings and petterns at the first beginning. Our rich-experienced engineers could support you from an initial idea to serial production with there expert knowledge of real manufacturing and material analysis including chemical composition and mechanical properties. Our engineering team will convert any of development to a lean and production-friendly design taking into our full process production chain.

At our pattern and tools shop, our experienced pattern makers and technicans could use the 2D drawings and 3D models for the tooling / pattern development. If possible, the traditional way of making is also considered. Our experts could also support you in making 3D models as per your rough idea or 2D drawings, if you need.

▶ When we design the toolings/patters and the production procedure of the sand casting, we always think about the following main factors:

• Lower weight of castings to reduce your costs.

• Accurate dimension to reduce or delete the need for machining.

• Easy to install with other components.

• Suitable casting metals to meet the requirements of mechanical properties but control the whole costs.

• Be conductive to mass casting production.

• Environment-friendly.

▶ Metallurgy, Chemical Composition and Mechanical Properties of the Material

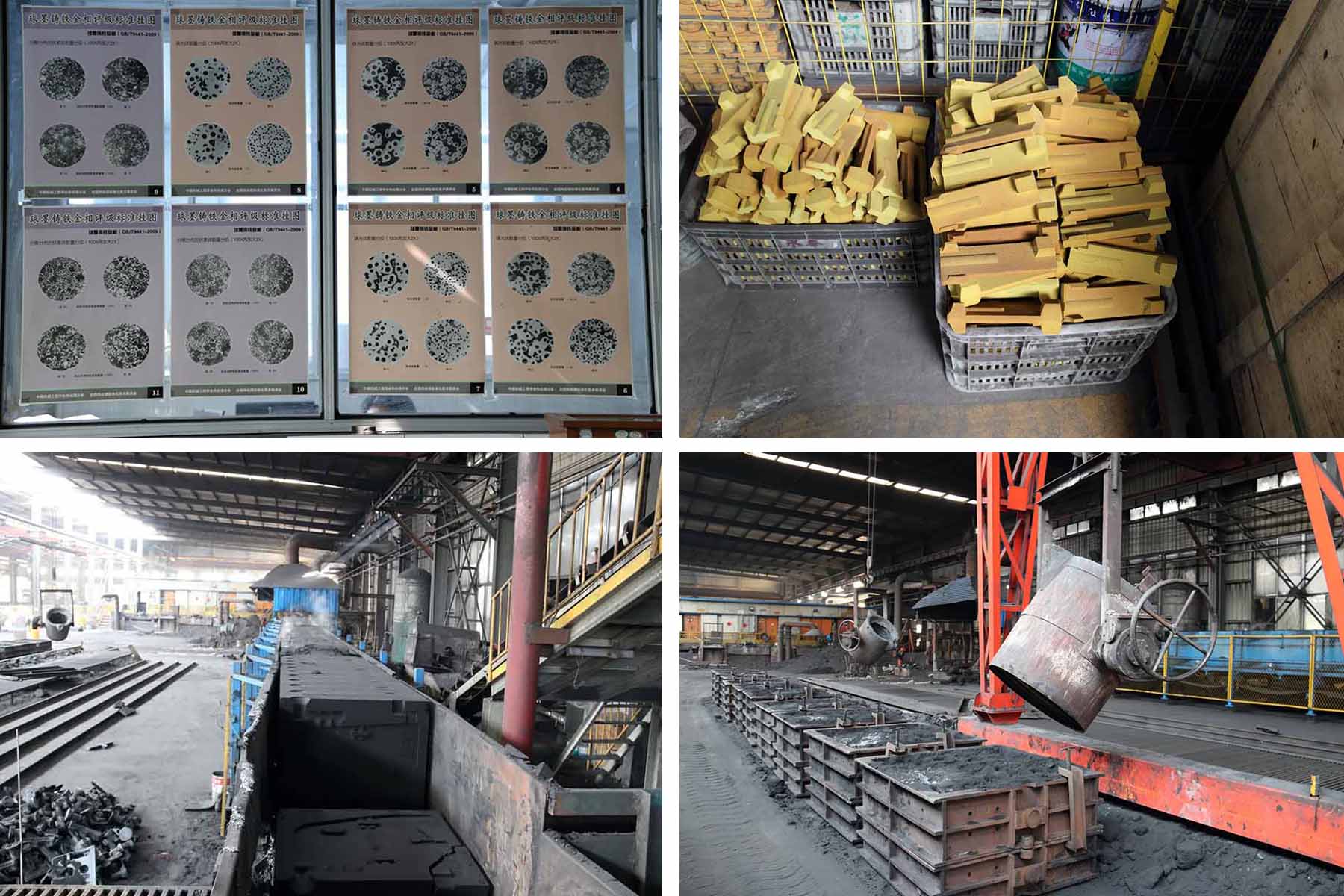

The sand casting foundry at RMC is equipped with a complete metallurgical laboratory to determin the chemical and mechanical characteristics of each melt and to analyse the metallurgic condition of the molten metal before pouring. Microsections are examined under the microscope to obtain final information. If possible or needed, we can issure 3.1 Certificate for each delivery part on customers' demand.

▶ What Iron Sand Castings We Can Produce:

• Max Size: 1,500 mm × 1000 mm × 500 mm

• Weight Range: 0.5 kg - 500 kg

• Annual Capacity: 5,000 tons - 6,000 tons

• Dimensional Tolerances: On Request or Standard (ISO8062-2013 or GB/T 6414-1999)

• Mold Materials: Green Sand Casting, Resin Coated Shell Mold Sand Casting, Dry Sand (Lost Foam Casting, Vacuum Casting)

▶ Capabilities of Sand Casting by Automatic Sand Molding Machines:

• Max Size of Finished Castings: 1,000 mm × 800 mm × 500 mm

• Unit Weight Range of Sand Casting: 0.5 kg - 500 kg

• Annual Capacity of Sand Castings: 8,000 tons - 10,000 tons

• Dimensional Tolerances of Sand Casting: On Request or According to ISO8062-2013 or GB/T 6414-1999

• Molding Materials: Green Sand Casting, Resin Coated Sand Shell Molding Casting.

▶ What Cast Iron We Cast by Sand Casting Process:

• Gray Iron: HT150, HT200, HT250, HT300, HT350; GJL-100, GJL-150, GJL-200, GJL-250, GJL-300, GJL-350; GG10~GG40.

• Ductile Iron or Nodular Iron: GGG40, GGG50, GGG60, GGG70, GGG80; GJS-400-18, GJS-40-15, GJS-450-10, GJS-500-7, GJS-600-3, GJS-700-2, GJS-800-2; QT400-18, QT450-10, QT500-7, QT600-3, QT700-2, QT800-2;

• White Iron

• Compacted Graphite Iron

• Malleable Iron.

▶ Steps of Sand Casting:

• Patterns & Tooling Design → Making Patterns → Moulding Process → Chemical Composition Analysis → Melting & Pouring → Cleaning, Grinding & Shot Blasting → Post Processing or Packing for Shipment

▶ What Measures We Take to Inspect the Sand Castings:

• Spectrographic and manual quantitative analysis

• Metallographic analysis

• Brinell, Rockwell and Vickers hardness inspection

• Mechanical property analysis

• Low and normal temperature impact testing

• Cleanliness inspection

• UT, MT and RT inspection

▶ What Further Process We Can Do after Sand Casting:

• Deburring & Cleaning

• Shot Blasting / Sand Peening

• Heat Treatment: Normalization, Quench, Tempering, Carburization, Nitriding

• Surface Treatment: Passivation, Anodizing, Electroplating, Hot Zinc Plating, Zinc Plating, Nickel Plating, Polishing, Electro-Polishing, Painting, GeoMet, Zintec

• Machining: Turning, Milling, Lathing, Drilling, Honing, Grinding,

русский

русский