Products made by Gray Iron Sand Casting in China

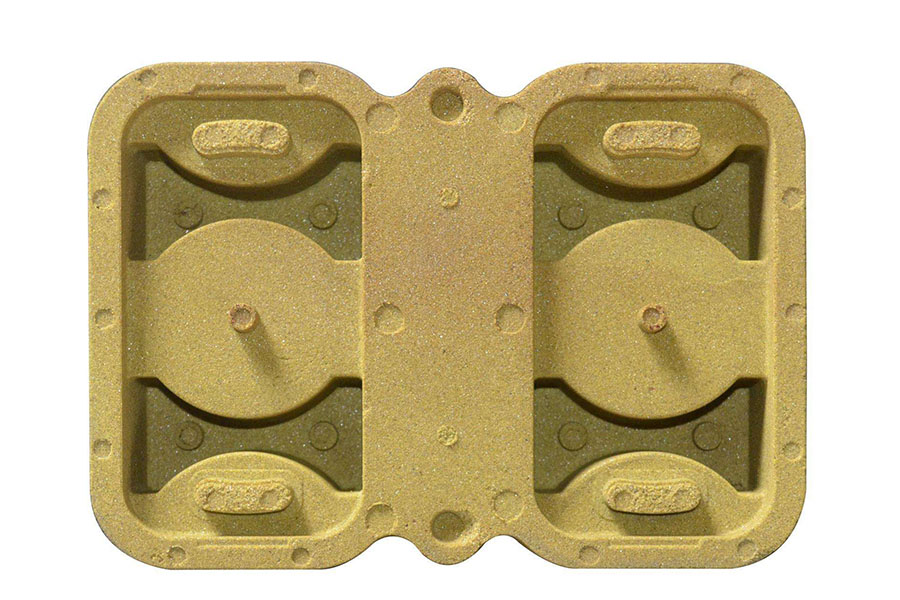

Material: Grey Cast Iron Process: Sand Casting and CNC Machining Weight: 6.20 kg Application: Heavy Truck

Custom OEM Products made by Gray Iron Sand Casting in China

Description

Custom OEM Products made by Gray Iron Sand Casting in China

Sand casting is one of the most popular and simplest types of casting. Sand casting allows for smaller batches than permanent mold casting and at a very reasonable cost. Not only does this method allow manufacturers to create products at a low cost, but there are other benefits to sand casting, such as very small-size operations. Sand casting also allows most metals to be cast, depending on the type of sand used for the molds.

Sand casting is suitable for large-part production. Green (moist) sand casting process has almost no limitation of weight. The sand is bonded together using clay, chemical binders, or polymerized oils (such as motor oil). Sand can be recycled many times in most operations and requires little maintenance. In modern real production, the shell molded casting processes is used due to the better surface and less need of secondary machining processes.

Shell molding casting process is also called pre-coated resin sand casting process, hot shell molding castings or core casting process. The main molding material is the pre-coated phenolic resin sand, which is more expensive than green sand and furan resin sand. Moreover, this sand can not be recycle used. The shell molding iron casting parts have higher costs than sand casting. However, the shell molding casting parts have many advantages such as tighter dimensional tolerance, good surface quality and less casting defects.

▶ Raw Materials of Cast Iron as per standard or customized chemical compositions and mechanical properties.

• Gray Iron: HT150, HT200, HT250, HT300, HT350; GJL-100, GJL-150, GJL-200, GJL-250, GJL-300, GJL-350; GG10~GG40.

• Ductile Iron or Nodular Iron: GGG40, GGG50, GGG60, GGG70, GGG80; GJS-400-18, GJS-40-15, GJS-450-10, GJS-500-7, GJS-600-3, GJS-700-2, GJS-800-2; QT400-18, QT450-10, QT500-7, QT600-3, QT700-2, QT800-2.

▶ Capabilities of Cast Iron Green Sand Casting Components

✔ By handle mould:

• Max Size: 1,500 mm × 1000 mm × 500 mm

• Weight Range: 0.5 kg - 500 kg

• Annual Capacity: 5,000 tons - 6,000 tons

• Tolerances: On Request.

✔ By Automatic Molding Machines:

• Max Size: 1,000 mm × 800 mm × 500 mm

• Weight Range: 0.5 kg - 500 kg

• Annual Capacity: 8,000 tons - 10,000 tons

• Tolerances: On Request.

▶ Capabilities of Cast Iron Shell Molding Casting Components

• Max Size: 800 mm × 600 mm × 500 mm

• Weight Range: 0.5 kg - 300 kg

• Annual Capacity: 5,000 tons - 8,000 tons

• Tolerances: On Request.

▶ How We Inspect the Cast Iron Components:

• Spectrographic and manual quantitative analysis

• Metallographic analysis

• Brinell, Rockwell and Vickers hardness inspection

• Mechanical property analysis

• Low and normal temperature impact testing

• Cleanliness inspection

• UT, MT and RT inspection

▶ Post-Casting Process

• Deburring & Cleaning

• Shot Blasting / Sand Peening

• Heat Treatment: Normalization, Quench, Tempering, Carburization, Nitriding

• Surface Treatment: Passivation, Anodizing, Electroplating, Hot Zinc Plating, Zinc Plating, Nickel Plating, Polishing, Electro-Polishing, Painting, GeoMet, Zintec

• Machining: Turning, Milling, Lathing, Drilling, Honing, Grinding,

▶ Advantages of Cast Iron by Sand Casting or Shell Molding Casting

• Low Cost due to its cheap and recyclable mold materials and simple production equipment.

• Wide range of unit weight from 0.10 kg to 500 kgs or even bigger.

• Various Structure from simple type to complex type.

• Suitable for production requirements of various quantity.

русский

русский