Brass and Bronze Sand Casting Foundry in China

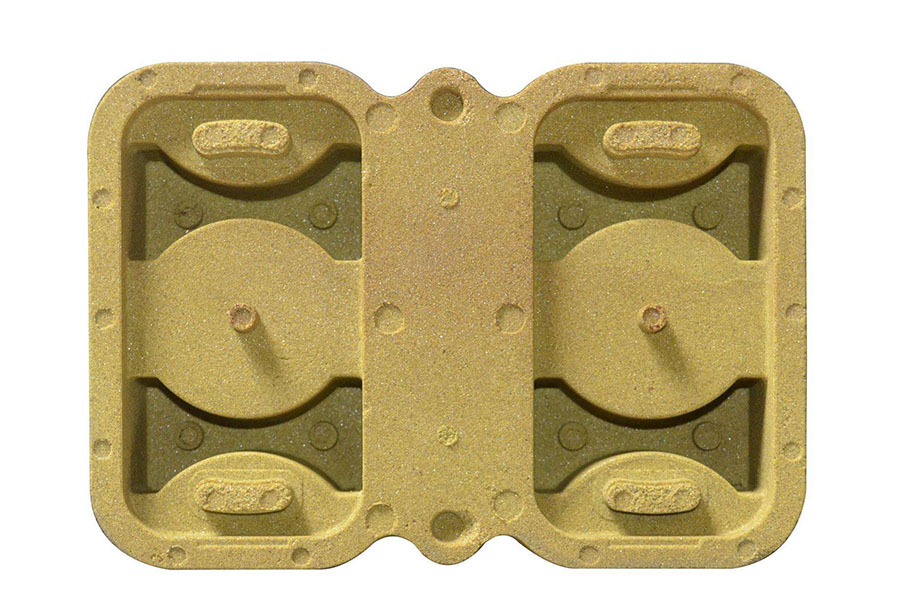

Material: Brass, Bronze and other Copper Alloys Process: Green Sand or Shell Molding Casting Weight: 6.20 kg Application: Filter

Brass and Bronze Sand Casting Foundry in China with OEM Custom Services as per your drawings or samples.

Brass and Bronze Sand Casting Foundry in China with OEM Custom Services as per your drawings or samples.

Brass is an alloy composed of copper and zinc. Brass composed of copper and zinc is called ordinary brass. If it is a variety of alloys composed of more than two elements, it is called special brass. Brass is a copper alloy with zinc as the main element. As the zinc content increases, the strength and plasticity of the alloy increase significantly, but the mechanical properties will decrease significantly after exceeding 47%, so the zinc content of brass is less than 47%. In addition to zinc, cast brass often contains alloying elements such as silicon, manganese, aluminum, and lead. Casting brass has higher mechanical properties than bronze, but the price is lower than bronze. Cast brass is often used for general purpose bearing bushes, bushings, gears and other wear-resistant parts and valves and other corrosion-resistant parts. Brass has strong wear resistance. Brass is often used to make valves, water pipes, connecting pipes for internal and external air conditioners, and radiators.

▶ Capabilities of Sand Casting moulded by hand:

• Max Size: 1,500 mm × 1000 mm × 500 mm

• Weight Range: 0.5 kg - 500 kg

• Annual Capacity: 5,000 tons - 6,000 tons

• Tolerances: On Request or Standard

• Mold Materials: Green Sand Casting, Shell Mold Sand Casting.

▶ Capabilities of Sand Casting by Automatic Molding Machines:

• Max Size: 1,000 mm × 800 mm × 500 mm

• Weight Range: 0.5 kg - 500 kg

• Annual Capacity: 8,000 tons - 10,000 tons

• Tolerances: On Request.

• Mold Materials: Green Sand Casting, Shell Mold Sand Casting.

▶ Materials Available for Sand Casting Foundry at RMC:

• Brass, Red Copper, Bronze or other Copper-based alloy metals: ZCuZn39Pb3, ZCuZn39Pb2, ZCuZn38Mn2Pb2, ZCuZn40Pb2, ZCuZn16Si4

• Gray Iron: HT150, HT200, HT250, HT300, HT350; GJL-100, GJL-150, GJL-200, GJL-250, GJL-300, GJL-350; GG10~GG40.

• Ductile Iron or Nodular Iron: GGG40, GGG50, GGG60, GGG70, GGG80; GJS-400-18, GJS-40-15, GJS-450-10, GJS-500-7, GJS-600-3, GJS-700-2, GJS-800-2; QT400-18, QT450-10, QT500-7, QT600-3, QT700-2, QT800-2;

• Aluminium and Their Alloys

• Other Materials as per your unique requirements or according to ASTM, SAE, AISI, ACI, DIN, EN, ISO, and GB standards

| PROCESS | MATERIAL | |

| Sand Casting | Green Sand | Grey Iron, Ductile Iron, Malleable Iron, Stainless Steel, Carbon Steel, Steel Alloys, Aluminum Alloy, Brass, etc |

| Furan Resin Sand | ||

| Shell Molded | ||

| Cold Harden Resin Sand | ||

| Investment Casting (Lost Wax Casting) | Water glass | Carbon Steel, Steel Alloys, Stainless Steel, Brass, other alloys |

| Silica Sol | ||

| Lost Foam Casting | Ductile iron GGG 40 to GGG 80 / Grey Iron | |

| ASTM 60-40-18 / 65-45-12 / 80-55-06 / 100-70-03 | ||

| Carbon steel, Hi-Mn steel, Hi-Cr steel | ||

| Austempering ductile iron | ||

| Heat resistant steel / Wear resistant steel | ||

| Forging | Open Forging | Stainless Steel, Carbon Steel, Alloy Steel, Brass, Aluminum |

| Die Forging | ||

| Roll Forging | ||

| Die Casting | High Pressure Die Casting | Aluminum, Zinc, Brass |

| Low Pressure Die Casting | ||

| Gravity Pressure Die Casting | ||

| Surface Finish | Powder Coating, Anodization, Electrophotesis, Chrome Plating, Painting, Sand blasting, Nickel Plating, Zinc Plating, Blacking, Polishing, Bluing, Geormet, Zintek, etc. | |

| CNC Precision Machining | Lathing, Milling, Turning, Honing, Drilling, Boring, Tapping, Wire Electrode Cutting, Grinding...etc. | |

| Inspection and Quality Control | Spectrum Analyzer, CMM, Hardness Tester, Tensile Strength Tester, Yild Strentgh Testor, Sealing Pressure Tester, Carbon Sulfur Analyzer, Metallurgical Microscopy, Press Force Tester...etc. | |

русский

русский