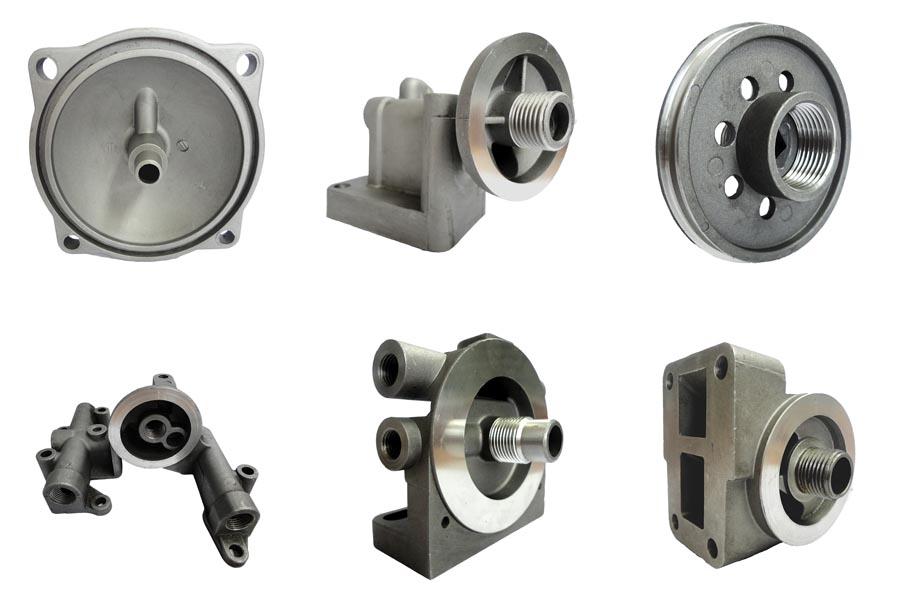

Aluminium Alloy CNC Machining Product

Material: Aluminium Alloy Process: Die Casting + CNC Machining Weight: 4.62 kg Application: Truck Spare Parts

China CNC machining of Aluminium alloy with one stop solution from casting, heat treatment, surface treatment and precision machining.

Description

Aluminium alloy is usually cast by gravity casting (die mold), low pressure casting and high pressure die casting. The CNC machining is also needed if the fine finish and high precision accuracy are needed.

CNC Precision Machining Capabilities |

|||

| Facilities | Quantity | Size Range (mm) | Annual Capacity |

| Vertical Machining Center (VMC) | 48 sets | 1,500 × 1,000 × 800 | 6,000 tonn or 300,000 pieces |

| Horizontal Machining Center (VMC) | 12 sets | 1,200 × 800 × 600 | 2,000 tons or 100,000 pieces |

| CNC Machine | 60 sets | Max turning φ600 | 5,000 tons or 600,000 pieces |

| Standard of Tolerance: ISO 8062 2013, ISO 2768, GOST 26645 (Russia) or GBT 6414 (China). | |||

▶ Equipment for Precision Machining Components:

- Convertional Machining Machines: 20 sets.

- CNC Machines: 60 sets.

- 3-Axis Machining Center: 10 sets.

- 4-Axis Machining Center: 5 sets.

- 5-Axis Machining Center: 2 sets

▶ Precision Machining Capabilities

- Max Size: 1,500 mm × 800 mm × 500 mm

- Weight Range: 0.1 kg - 500 kg

- Annual Capacity: 10,000 tons

- Accuracy: As per standards: .... or on request. Minimum ±0.003 mm

- Holes to ±0.002 mm dia.

- Flatness, Roundness and Straightness: As per standards or on request.

▶ Available Process

- Turning

- Milling

- Lathing

- Drilling

- Honing, Grinding.

- Washing

▶ Available Ferrous Metal Materials for Precision Machining Components:

- Cast Iron including gray iron and ductile iron

- Carbon Steel from low carbon steel, medium carbon steel and high carbon steel.

- Steel Alloys from standard grades to special grades on request.

- Aluminum and their alloys

- Brass and Copper

- Zinc and their alloys

- Stainless Steel, Duplex, Corrosion-resistant Steel, High-temperature Steel.

Typical Chemical Composition of Investment Casting Aluminium Alloy by North American Specifications |

||||||||||||||

| Alloy Grade | Specification | Al | Cu | Si | Zn | Mg | Cr | Fe | Mn | Ti | Ag | Be | Ni | P |

| A356-T6 | AMS 4218 | Bal | 0.20 | 6. 5 - 7. 5 | 0.10 | 0.25-0.45 | - | 0.20 | 0.10 | 0.20 | - | -- | - | - |

| A 357 | AMS 4219 | Bal | 0.20 | 6. 5 - 7. 5 | 0.10 | 0.40-.70 | - | 0.20 | 0.10 | 0.04-0.20 | - | 0.04-0.07 | - | - |

| F 357 | AMS 4289 | Bal | 0.20 | 6.5-7.5 | 0.10 | 0.40-.70 | - | 0.10 | 0.10 | 0.04-0.20 | - | 0.002 | - | - |

| E 357 | AMS 4288 | Bal | - | 6.5-7.5 | 0.10 | 0.55-0.60 | - | 0.10 | 0.10 | 0.10-0.20 | - | 0.002 | - | - |

| A201 | AMS 4229 | Bal | 4.0-5.0 | 0.05 | - | 0.15-0.35 | - | 0.10 | 0.20-0.34 | 0.15-0.35 | 0.40-1.0 | - | - | - |

| C355 | AMS 4215 | Bal | 1.0-1.5 | 4.5-5.5 | 0.10 | 0.40-0.60 | - | 0.20 | 0.10max | 0.20 | - | - | - | - |

| A206 | AMS 4235 | Bal | 4.2-5.0 | .05max | 0.05max | 0.20-0.35 | - | 0.10ma | 0.20-0.50 | 0.15-0.30 | - | - | 0.5max | - |

| B206 | Bal | 4.2-5.0 | .05max | 0.05max | 0.15-0.35 | - | 0.10max | 0.20-0.50 | 0 1 0 | - | - | 0.5max | - | |

русский

русский