RMC was originally developed from a machining factory set up at 1999 when we only had several simple vertical lathes and milling machines. Along with the booming of precision casting industry in Shandong area, we expanded our business to more OEM industries.

Up to now, our own investment casting foundry is equipped with two production lines of lost wax casting; our in-house machining workshop has advanced CNC turning lathes, milling machines and machining centers. RMC investment casting foundry now has the capacity of producing 2000 tons steel casting with precision machining. RMC investment casting foundry is specializing in low carbon steel, stainless steel and alloy steel casting. We can use three different bonded materials for different kinds of lost wax castings: silica sol, water glass and their mixtures.

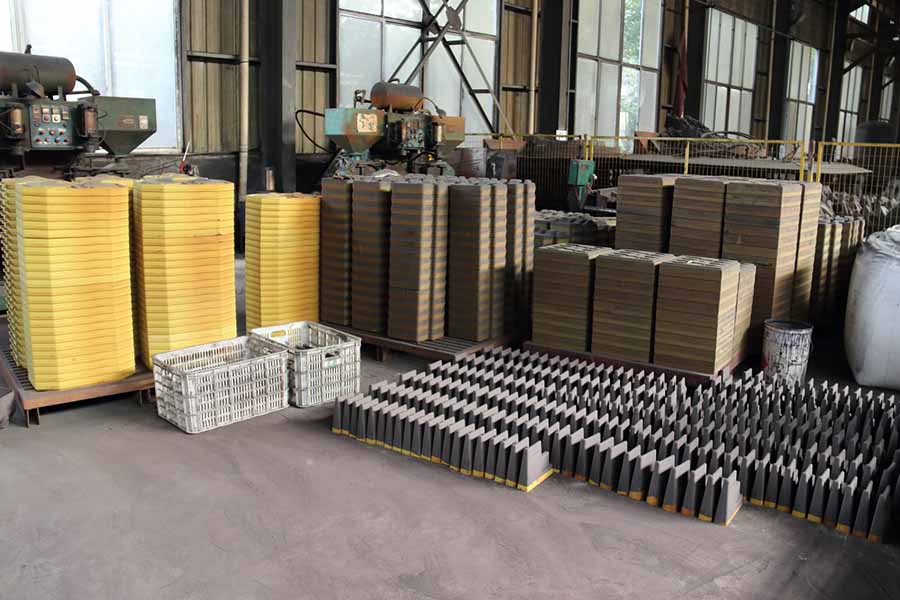

With automatic sand casting production lines including toolings making facilities, automatic molding making machines, shot blasting machines, automatic grinding and cleaning machines, painting lines and packing facilities, our sand casting foundry has a big advantages in capacity and quality control. Shell mold casting, as a more precisely casting process, is also available in RMC now to reach the unique requirements from our esteemed customers in different OEM industries.

After cooperating for many years and challenging projects, we have established a good relationship with our contracting partners from casting + machining, die casting, precision forging, heat treatment, surface treatment and other manufacturing industries. And we have also obtained rich experience on how to control the quality and delivery time by communicating and managing our partners. Based on the mutual benifits and respect with each other, our manufacturing partners are back on RMC, of course, back our customers as well.

Our Future Strategies

In the future, RMC plans to reinforce our market position as one of the leading precision component companies. The following ideas are the concepts we insist to held:

- Continue focusing on high precision, high complexity and function oriented products and provide "One Stop Solutions”

- Deepen relationship with current major customers and develop new chances with other global industry leading customers

- Reinforce our existing leading position in certain end-markets and focus on increasing presence in additional selected areas with growth prospect

- Continue to invest in R&D to optimize production processes and improve operational efficiency

русский

русский