Custom Metal Castings Manufacturer in China

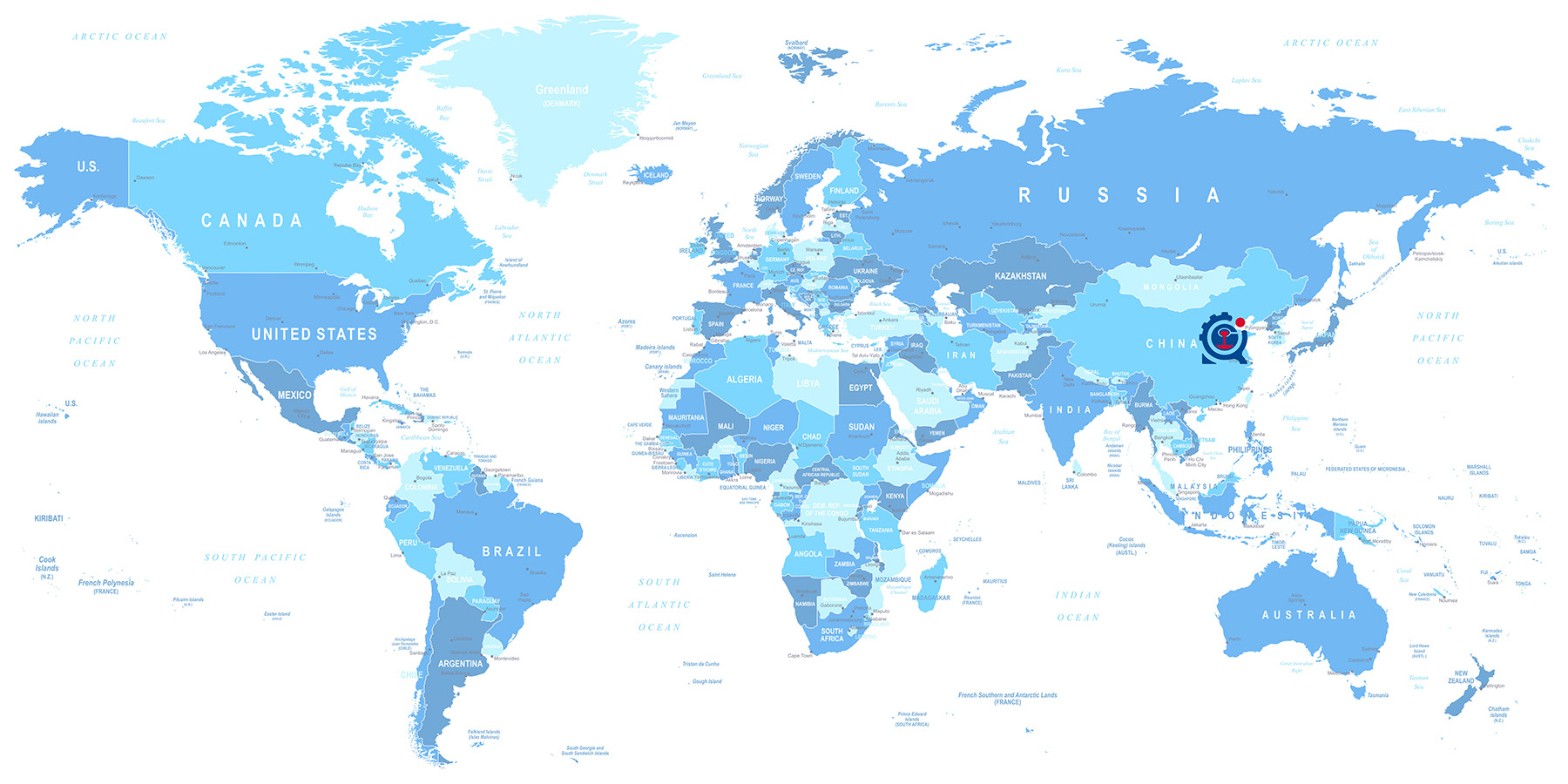

RMC was founded in 1999 by our founding team based in Qingdao, Shangdong, China. With its foundry and machining workshop also in Shandong province, we have now grown to become one of the finest metal forming companies with processes of sand casting, lost wax casting (investment casting), shell mold casting, lost foam casting, vacuum casting, precision forging, machining and post-processes such as surface treatment and heat treatment.

As a full service metal casting company, RMC have redundant manufacturing capabilities that enable us to produce top quality products for our customers. We also offer outsourced castings, forgings, metalworks, heat treatment and surface treatment from other contracting partners in China to provide a cost effective alternative with short lead time.

RMC is a global oriented manufacturer of high precision, high complexity and mission critical casting and CNC precision machined parts for diverse end markets. We have been enjoying a high reputation from our global emerging position by our integrated business model with comprehensive capabilities of offering one stop solutions for custom metal components.

From pattern design to finished parts, we can do whatever you need for OEM custom metal parts. With our well organized facilities and professional colleagues and engineers, we utilize the new advanced technologies which helps us produce complex, high precision, near-net-shape metal parts made of ferrous and non-ferrous metals.

What We Do

RMC is an ISO 9001 certified foundry and precision machining factory. As a professional provider, our capabilities mainly cover investment casting, sand casting, shell casting, vacuum casting, lost foam casting, forging and secondary process including CNC machining, heat treatment, surface treatment, packing, logistics and comprehensive service in a wide variety of materials including gray iron, ductile iron, stainless steel, alloy steel, carbon steel, wear-resistant and heat-resistant steel, aluminium, brass, zinc and various other high alloy materials.

Our colleagues in the engineering team take it as a priority to understand the unique needs and requirements of our diverse customers from different industries so we can provide the suitable materials and production process. RMC produces sand molds using the green sand casting, shell molded casting (pre-coated type) and furan sand molding system, allowing us great dimensional flexibility as well as the ability to pour castings up to several hundreds of kilograms. We can produce steel castings up to 0.5 tons and iron castings up to 5 tons. RMC stores patterns for the customers in a separate workshop away from the daily operation of the foundry.

No matter what you need, single prototype part, small quantities order or high volume production runs, parts with a few grams or hundreds of kilograms, simple or complex designs, RMC is a Reliable Manufacturing Company who can do them all.

Quality Values

Based on the recognition that rigid quality control is paramount to our customers, we take quality as our self-esteem. Well organized equipment and knowledgeable employees are the keys to our outstanding record of quality. The strict internal standards in RMC require us to proceed strict testing and quality control procedures, beginning from the design stages all the way through final inspection. RMC is always willing to take additional steps in testing and quality control procedures so as to match or even beyond the most exacting customer requirements.

With fully-equipped materials testing laboratory and spectrometers, hardness and tensile testing machines, our colleagues could proceed the testing totally according to your unique strict requirements. We utilize NDT facility for in-house magnetic particle and liquid penetrant testing. Additionally, we can offer other test service with fully certified X ray and ultrasonic testing vendors in our area from the third-party.

Value Added Service

When you work with us, you're working with professional engineering team and a full comprehensive supply chain. We offer many competitive advantages, including rapid turn arounds on quotes, tooling & patterns, samples, and production work; integrated, flexible, and responsive manufacturing capabilities; competitive pricing; design assistance; stable and consistent quality, and complete material integrity. Our full-side service can be provide by effective communication, teamwork support, continuous improvement and out-sourced capabilities.

Usually our engineers are specialized in providing cost down plans or solutions through recommendation or consultation of :

- Durable and appropriate process.

- Appropriate material.

- Improved product design.

- Competitive solutions.

Design and Engineering

With the lastest state-of-the-art technology and dedicated workers, RMC will support you from the planning stage through to delivery. We involve the project together from engineering, designing, tool making, trial casting, measurement and mass production.

Our team designs and builds the casting and machining procedures by analysis and reverse engineering, offering cost-down proposals. We provide free design consultations and on the appropriate process and material according to your requirements and the real application. We make drawings for tooling with the aid of SolidWorks/Pro-E/UG or other professional software for a better idea of the desired metal components.

Who We Serve

RMC serves the companies in different industries from China to overseas, including but not limited to Australia, Spain, UAE, Israel, Italy, Germany, Norway, Russia, the U.S.A., Colombia, Japan, Sweden, the Netherlands, Bulgaria, Egypt, Brasil, Chile...etc. Many of our customers are from newly emerged companies to well recognized global leaders in their respective industries. Some of the industries we serve include:

|

• Automotive |

• Heavy Duty Truck< |

|

• Hydraulics |

• Agricultural Machinery |

|

• Rail Freight Cars |

• Logistics Machinery |

|

• Construction Machinery |

• Other Machinery |

русский

русский