In investment casting, a shape or replica is formed (usually out of wax) and placed inside a metal cylinder called a flask. Wet plaster is poured into the cylinder around the wax shape. After the plaster has hardened, the cylinder containing the wax pattern and plaster is placed in a kiln and is heated until the wax has fully vaporized. After the wax has fully burnt-out (de-waxing), the flask is removed from the oven, and molten metal (usually alloy steel, stainless steel, brass...etc) is poured into the cavity left by the wax. When the metal has cooled and solidified, plaster is chipped away, and the metal casting is revealed.

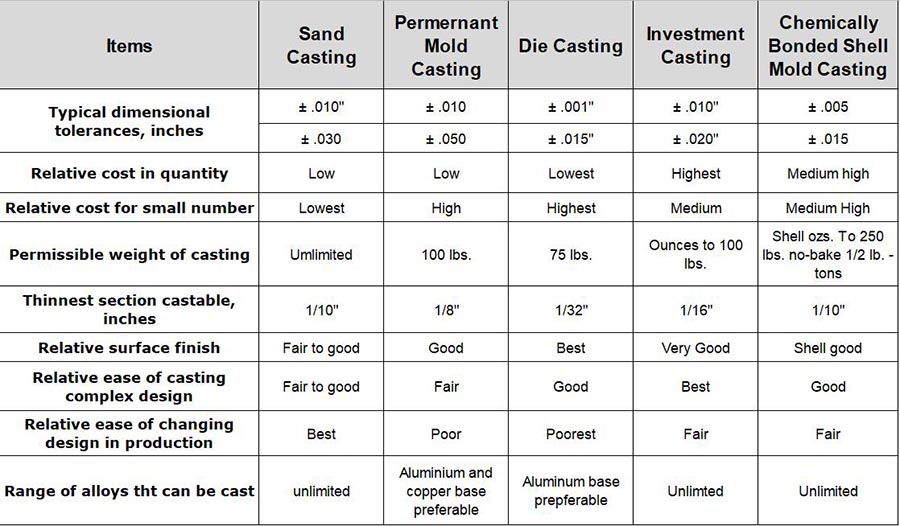

Casting is very useful for creating sculptural objects or engineering shapes with complex geometry in metal. Cast parts have a unique look to them, quite different from machined parts. Some shapes which would be difficult to machine are more easily cast. There is also less material waste for most shapes, since unlike machining, casting is not a subtractive process. However, the precision achievable through casting is not as good as machining.

When Should You Choose Investment Casting and When Should You Choose Sand Casting?

One big advantage of investment casting is that it can allow for undercuts in the pattern, while sand casting does not. In sand casting, the pattern needs to be pulled out of the sand after it is packed, whereas in investment casting the pattern is vaporized with heat. Hollow castings and thinner sections can also be made more readily with investment casting, and a better surface finish is generally achieved. On the other hand, investment casting is a much more timely and expensive process, and can have a lower success rate than sand casting does since there are more steps in the process and more opportunities for things to go wrong.

Quick Links:

Sand Casting | Investment Casting | CNC Machining | Lost Foam Casting | Vacuum Casting | Get a Quote

русский

русский