Stainless steel is a commonly used alloy in precision investment casting. Because stainless steel has excellent properties such as corrosion resistance and oxidation resistance, stainless steel castings are also widely used in various industrial fields.

High-alloy corrosion-resistant stainless steel, also known as stainless acid-resistant steel, is mainly used in various corrosion-resistant media conditions. The chromium content in typical stainless steel castings is generally above 12%. In addition, some other alloying elements are often added to stainless steel, such as nickel, molybdenum, copper, titanium, nitrogen and so on. According to the chemical composition and metallographic structure of stainless steel, stainless steel is divided into martensitic stainless steel, ferritic stainless steel, austenitic stainless steel and duplex stainless steel.

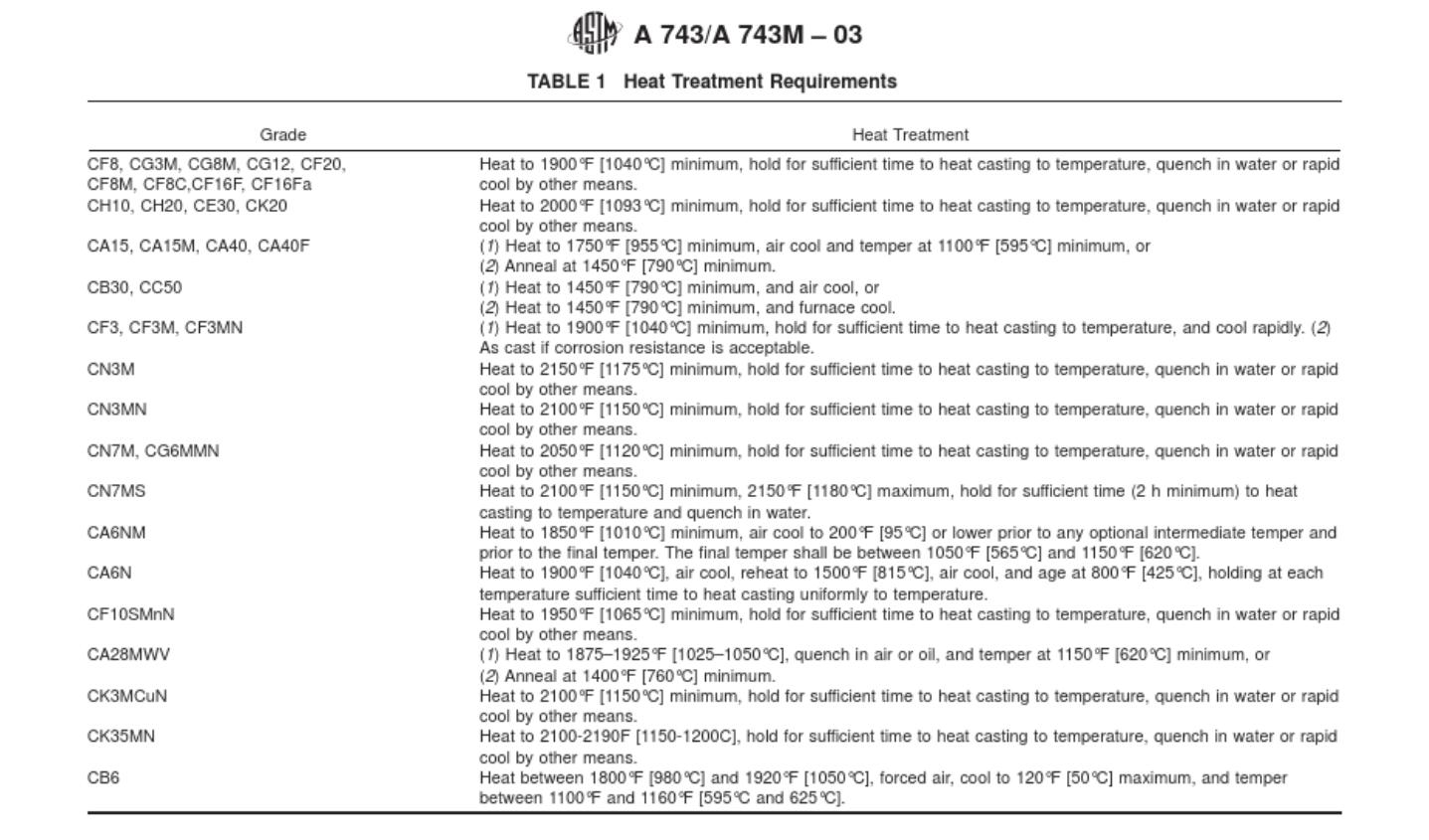

The heat treatment of stainless steel castings can greatly promote the performance and stability of the castings. According to ASTM A743 / A743M-03, Standard Specification for Castings, Iron-Chromium, Iron-Chromium-Nickel, Corrosion Resistant, for General Application, the following table describes the heat treatment of some common American grades of corrosion-resistant stainless steel and its alloys.

русский

русский