What is Investment Casting?

Investment casting, also known as the lost-wax process, is one of the oldest metal-forming techniques, spanning the last 5,000 years. The investment casting process begins with injecting engineered wax into high precision dies or with printed rapid prototypes. The wax patterns that are produced through either method are then assembled onto a sprue along with a ceramic pour cup.

These wax setups are then invested, or surrounded, with a silica slurry mixture and refractory zircon sand. Many coats are applied until a hard shell covers the assembled wax patterns. This is generally the longest stage in the investment casting process since the shell must dry completely before applying additional coats. Humidity and circulation play large factors in the successful execution of this stage.

Once the shell has properly dried, the wax patterns inside are burned out through a strong heated pressure chamber called an autoclave. Once all wax is removed, the shell cavity remains; an exact duplicate of the desired part.

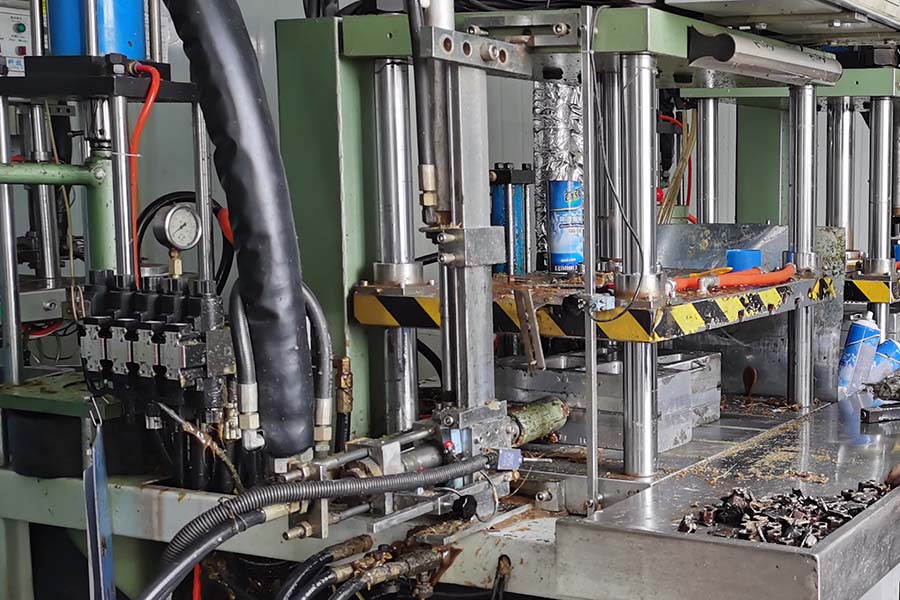

The desired alloy is then poured into the cavity. These alloys can include, but are not limited to, stainless-steel alloys, brass, aluminum, or carbon steel. After the molds cool, they head to finishing where the ceramic shell is taken off the metal parts. The parts are then cut off the sprue, sent to blast, grind, and other secondary finishing operations depending on the parts requirements.

Investment Casting Advantages

While there are many methods of metal-forming, investment casting is unique because it allows you to obtain highly complex shapes, much like high pressure die casting, but in both ferrous and non-ferrous materials.

Benefits of investment casting compared to other metal-forming processes:

The hardness and grain structure of the refractory materials used allows for superior surface qualities.

Better surface finish generally means a reduced need for secondary machine processes.

Per-unit costs decrease with large volume, if automation can be utilized to reduce labor.

Hard Tooling has a much longer life-span than other casting processes, as the wax that is injected is not very abrasive.

Can produce complicated shapes that would very difficult or impossible with other casting methods.

Can achieve high tolerances as well as undercuts that are not easily formed in high pressure die castings.

RMC: Your Choice for Investment Casting

With Engineering resources at all three domestic locations, a New Product Development (NPD) team, a sales force spanning coast to coast, and over 20 years in the industry, we can help save you time and money through expedited program management and speed to market.

русский

русский